Polishing

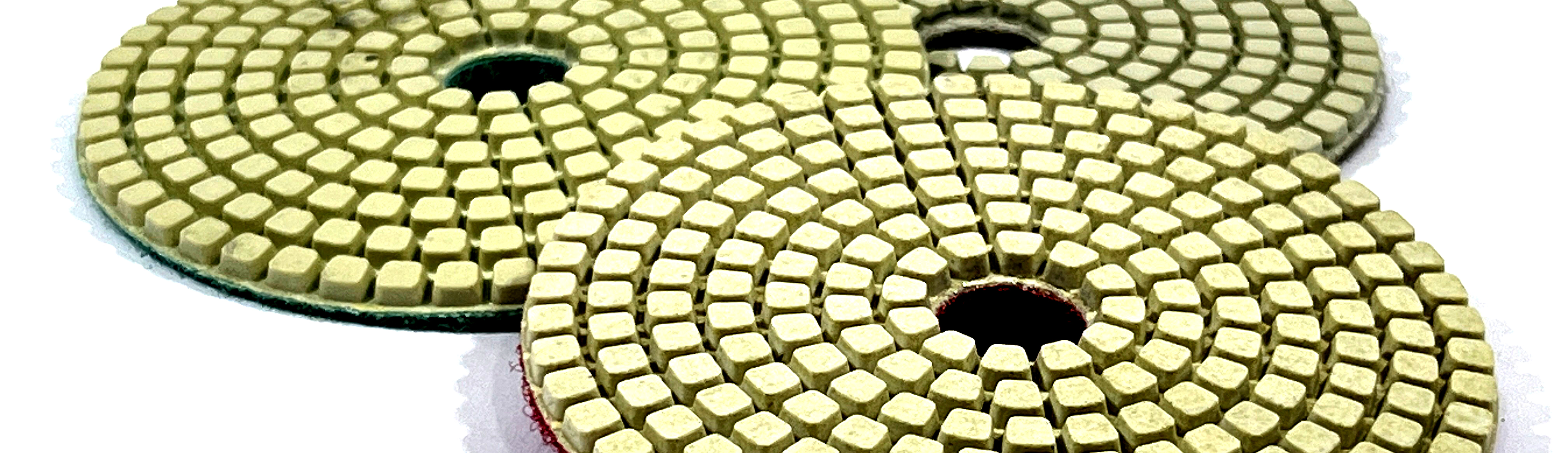

The polishing pads and chamfering wheels for the sander is a tool designed for smoothing and polishing surfaces. These tools are made from a mixture of materials containing a ceramic binder and a mixture of top quality diamonds, or a combination of polishing pastes, waxes or acid to increase their efficiency.

A polishing wheel on a sander can help you achieve a perfect surface that will not only be smooth, but also aesthetically pleasing. Whether you work with stone, concrete or ceramics. With the right choice and patient work, you will get maximum brilliant shine with deep color.

...(continuation of the article below, under products)

Why is a polishing wheel on a grinder worthwhile?

- High efficiency: The polishing disc on the sander enables fast and efficient smoothing and polishing of surfaces.

- Precise work: Thanks to the disc, you can achieve a perfectly smooth and shiny surface.

- Versatility: You can use the polishing wheels on the sander on different types of surfaces.

How to choose the right polishing wheel for a grinder?

Consider several factors when choosing a polishing wheel for your grinder:

- Choose a wheel suitable for the material you plan to polish. We addressed the issue of how to recognize the material in this article.

- The roughness or graininess of the disc affects its aggressiveness. High grits (e.g. #400, #800, #1500, #3000 ...) or soft felt discs are suitable for fine polishing and finishing work, while coarse grits are suitable for rough material processing - grinding. We covered this topic in more detail in this article.

- Choose a polishing wheel for the sander that corresponds to the size and shape of the surface you will be polishing. Larger discs are suitable for large surfaces, while smaller discs are better for detailed work.

Tips for effective use of a polishing pads and chafering wheels on a sander

To get the best results when using a polishing wheel on your sander, follow these tips:

- Before polishing, thoroughly clean the surface of dust, dirt and grease. This will ensure that the polishing wheel on the sander will work efficiently.

- Choose a suitable polishing wheel. Do not forget that the process of polishing the stone cannot be accelerated. It is extremely important to have a perfectly prepared substrate - a flawlessly sanded surface finished with a fine sanding disc (e.g. #120, #220).

- Choose a suitable polishing set of diamond discs, or consult with a salesperson or technician

In the case of polishing with a felt disc, apply a suitable polishing paste, wax or polishing dust (hull) to the disc or directly to the surface of the material. - They increase the polishing efficiency and ensure a smooth surface. Dry polishing is also common. The advantage is almost immediate visual inspection of material processing and less demanding technical equipment. During work, it is necessary to pay attention to the optimal temperature between the tool and the material... "Because even stone can be burned".

- Use gentle and even movements when polishing. Avoid applying too much pressure, which could damage the disc or the material.

- Long polishing may cause overheating of the material and the disc. Work in short intervals and allow the material and wheel to cool between polishing steps.

- After each use, thoroughly clean the polishing disc on the sander from the remains of dust, polishing pastes and material.

- Always check the polishing wheel on the sander. If it shows signs of wear or damage, replace it with another one.

For what activities do you need a polishing wheel on a sander?

- Metal polishing: Achieve a high gloss and smooth surface on metal parts such as cars, motorcycles or tools.

- Wood finishing: Smooth wood surfaces and enhance the natural beauty of wood when making furniture or decorative items.

- Plastic polishing: Create a smooth and shiny surface on plastic parts such as models, toys or appliances.

- A polishing wheel on a grinder is an invaluable tool for anyone who is involved in finishing work on various materials. Similarly to grinding wheels, felt polishing wheel or pneumatic polisher. Shop cheaply too.Because quality tools are half the success...

Read our blog, Polishing stone like a pro. The procedures, tools and tools you need"