Grinding

Why is grinding such an important step in the material processing process?

Grinding is a primary and extremely important process during which the desired shape, plane, and unevenness are lost. Whether it's stone, concrete, conglomerate, ceramics, wood... it's always rough processing of the material, which leaves fine grooves and scratches. It is a process that is necessary for the next step - polishing ...

(Continuation of text below, under products)

M14

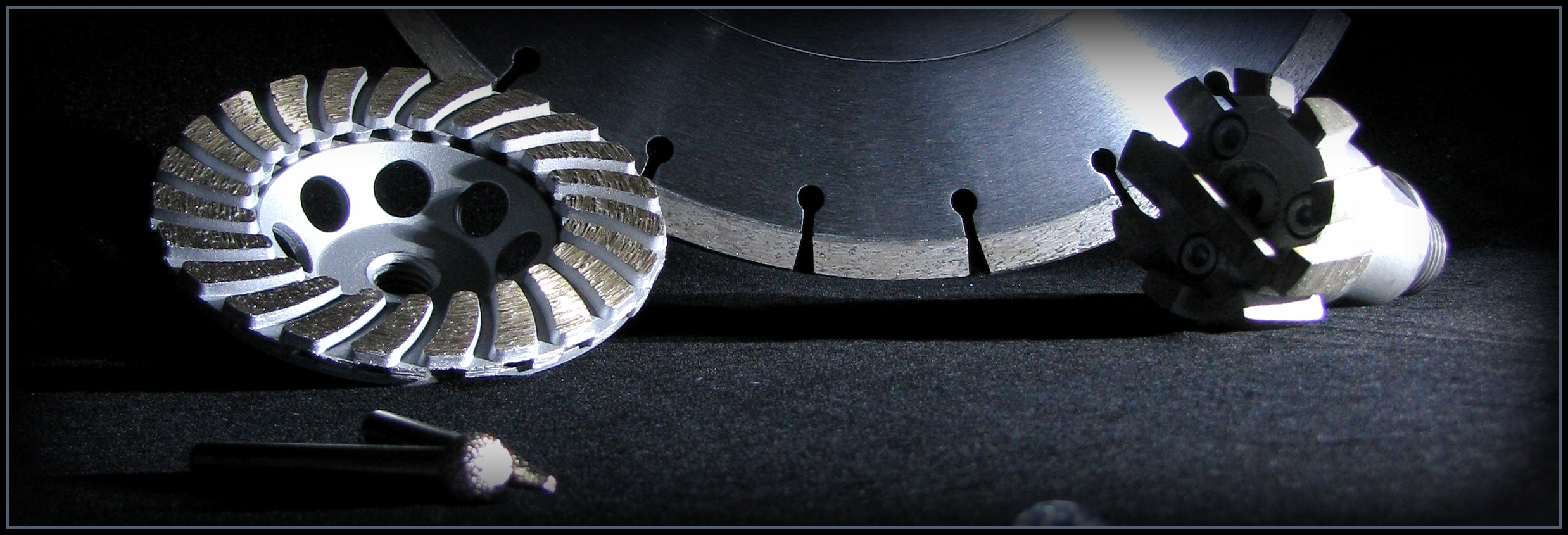

Grinding cups are used to prepare and smooth the surfaces of various materials. They are made of abrasive materials that remove excess material and leave a smooth surface. Abrasive discs are used in various industries related mainly to the construction field.

The main reason sanding wheels are so important is their ability to provide even and smooth surfaces, which is key to the final appearance and functionality of the product.The correct use of grinding wheels can significantly reduce the time required to complete a project and contribute to the expected quality of the result.

Various grinding wheels

Our offer is extremely diverse and includes grinding wheels for concrete, stone and paving. It is important to choose grinding wheels that are designed specifically for the material you are working with. Thickness is also an important aspect when choosing. Finer grit sanding wheels are designed for finishing and achieving a smooth surface, while coarser grit sanding wheels are used to remove more material and sand faster. It is important to consider what result you want to achieve and accordingly choose the correct roughness (grit - indicated by grid #) of the wheel.

How to use grinding wheels correctly?

- Make sure the surface is clean and dry before you start sanding. You will prevent the wheel from clogging and ensure even grinding.

- Use adequate pressure when sanding. Too much pressure can cause the wheel to overheat and wear quickly, while not enough pressure can lead to inefficient grinding.

- When sanding, move smoothly and evenly to achieve a surface without grooves and unevenness.

Common mistakes when using grinding wheels - how to avoid them?

Even experienced craftsmen can make mistakes when grinding stone, concrete or paving. Here are some of the most common:

- Wrong wheel selection: Make sure you are using the right sanding wheels for your project (concrete sanding wheel, stone sanding wheel, tile sanding wheel, table sander sanding wheels, etc.). The wrong wheel can damage the surface and reduce the quality of the result.

- Improper sander adjustment: An improperly adjusted sander can cause uneven sanding and damage to the wheel. Before starting work, always check the settings and make sure that the grinding wheels are not damaged or worn.

- Excessive pressure: Excessive pressure on grinding wheels can cause premature wear and damage to the surface. Grind slowly and evenly for best results.

- Overheating of the wheel: Overheating can occur if you put too much pressure on the sander or use unsuitable sanding wheels. Follow proper technique and use appropriate tools. Consult your choice of tool with the dealer.

- Wheel clogging: The cause of inefficient grinding is often grinding wheels clogged with dust and dirt. Therefore, clean the grinding wheels regularly to avoid this problem.

Read our blog on: The latest trends and techniques in stone and concrete grinding

In our offer you will find grinding tools in diameters from 30 millimeters to 180 millimeters, with grits from #16 (the coarsest) to #400 grit. Professional sculptors, stonemasons, builders, tilers, but also skilled hobby masters will find their own.

The selection is really varied. Do not hesitate to contact us for advice. We are here for you .... diasegment.sk@gmail.com