How to protect stones Stone surfaces such as marble, granite, sandstone and others are not only aesthetically pleasing, but also resistant and durable. However, in order to preserve their beauty and functionality, it is important to give them adequate care and protection.

Maybe we don't even realize it, but even such a perfect material as stone definitely needs to be treated, preserved or thoroughly cleaned. In the next few lines, we will mention some tips, advice and procedures on how to keep the stone in optimal condition and protect it from damage.

Why protect stone?

The stone can be susceptible to damage by various substances, such as acid, oil, wax, rust, or grease. An appropriately chosen impregnation creates a protective barrier that prevents these substances from penetrating the surface of the stone and causing permanent damage. Some types of stone can be sensitive to moisture, which can cause surface stains or later decay, erosion. The protective coating increases the stone's resistance to moisture and oils and protects it from these, not only aesthetic problems.

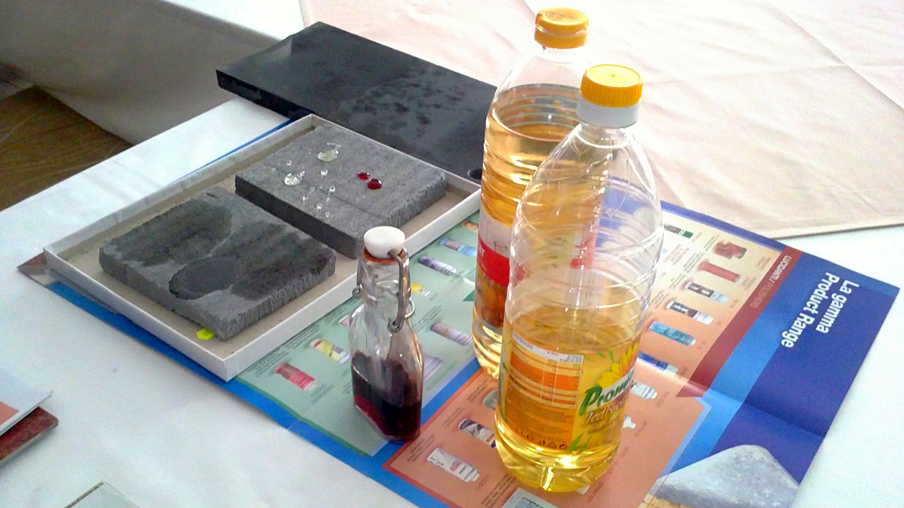

PHOTO: comparison of the material and the effect of oil and red wine on stone without impregnation (left) and with impregnation coating (right)

Choosing a suitable impregnation for stone surfaces

An extremely important point when choosing a suitable impregnation is consultation and professional advice with a trained worker. In case of unprofessional procedure and inappropriate choice of chemistry, permanent damage can occur. Another important step is the correct identification of the stone. For example, very often people confuse marble and granite. You can read more about this topic in the article Granite or marble?

Protective coatings

Protective coatings have one common feature, and that is the prevention of penetration of liquids and dirt deeper into the material. An essential property is vapor permeability, which is very important in exteriors with pavements or graves, where the protective coating does not let liquid in, but allows moisture to evaporate from the inside.

We also distinguish protective coatings according to their properties. Very popular are impregnations with the property "wet effect", which emphasize the color of the material more or less. In the offer you will find impregnations without color change, with a strengthening effect of stone or with a food certificate, which is applied primarily to surfaces where there is contact with food.

PHOTO: Stone impregnation with GREZZO product. The material is without surface treatment (in raw state) and the impregnation is freshly applied.

Stone cleaning

Before choosing the impregnation process, it is important to thoroughly clean the stone. Correct identification of the material is also extremely important here. For example, polished marble is susceptible to acidic environments. It means that by using an acid cleaner, you will lose the shine and you will only get it back by professional processing - machine polishing.

In our offer you will find cleaners for daily maintenance with a fine protective film, strong cleaners for organic pollution (natural moss, deposits...) and inorganic pollution (chemical - fixative, waxes...), acid-based cleaners (suitable for granite ) or alkaline base (suitable for marble, travertine, sandstone), strong rust removers, products for both professional and home use.

PHOTO: Cleaning stone using a cleaning pad

Stone impregnation

After thorough and deep cleaning of the stone, impregnation can come next. Applying a protective coating has several simple but extremely important steps:

Make sure that the stone is dry without deep moisture. Because where there is water, chemistry cannot get there and hard-to-remove stains can form.

Optimum external temperature 10-25 degrees (at high temperature the coating dries on the surface, deep impregnation does not occur).

Pay attention to the temperature of the material. During a summer day, the temperature of the stone can be very high.

Impregnation is applied in several thin layers with a roller, brush or cloth.

The first layer can be more abundant, as it soaks deeper into the material (it depends on the density - absorbency of the material).

The second layer - surface, is applied after complete soaking and drying of the first layer.

Additional layers are applied only if the impregnated material continues to absorb the impregnating substance.

The last layer can leave a fine film or powder that can be easily removed with steel wool.

You can perform a "wet sponge" test. Place the wet sponge on the impregnated surface and count the time it takes for a darker, soaked wet spot to appear under the sponge. You can compare with non-impregnated or raw surface.

How and where to choose protective coatings and what to pay attention to?

There are a large number of sellers and also a large number of brands that offer protective coatings for stone. Therefore, we recommend that you really consider the choice of product and consult the issue with a trained seller. Why? Because with stone impregnation you only have one attempt and a bad result can be definitive.

Photo: snapshot from the Bellinzoni training in 2012

Conclusion

Quality impregnation is not varnish or wax. It does not change the surface of the stone, does not fill the pores and does not increase the shine. It maintains an invisible protective film on the surface that prevents liquids from entering the material, it is a vapor barrier